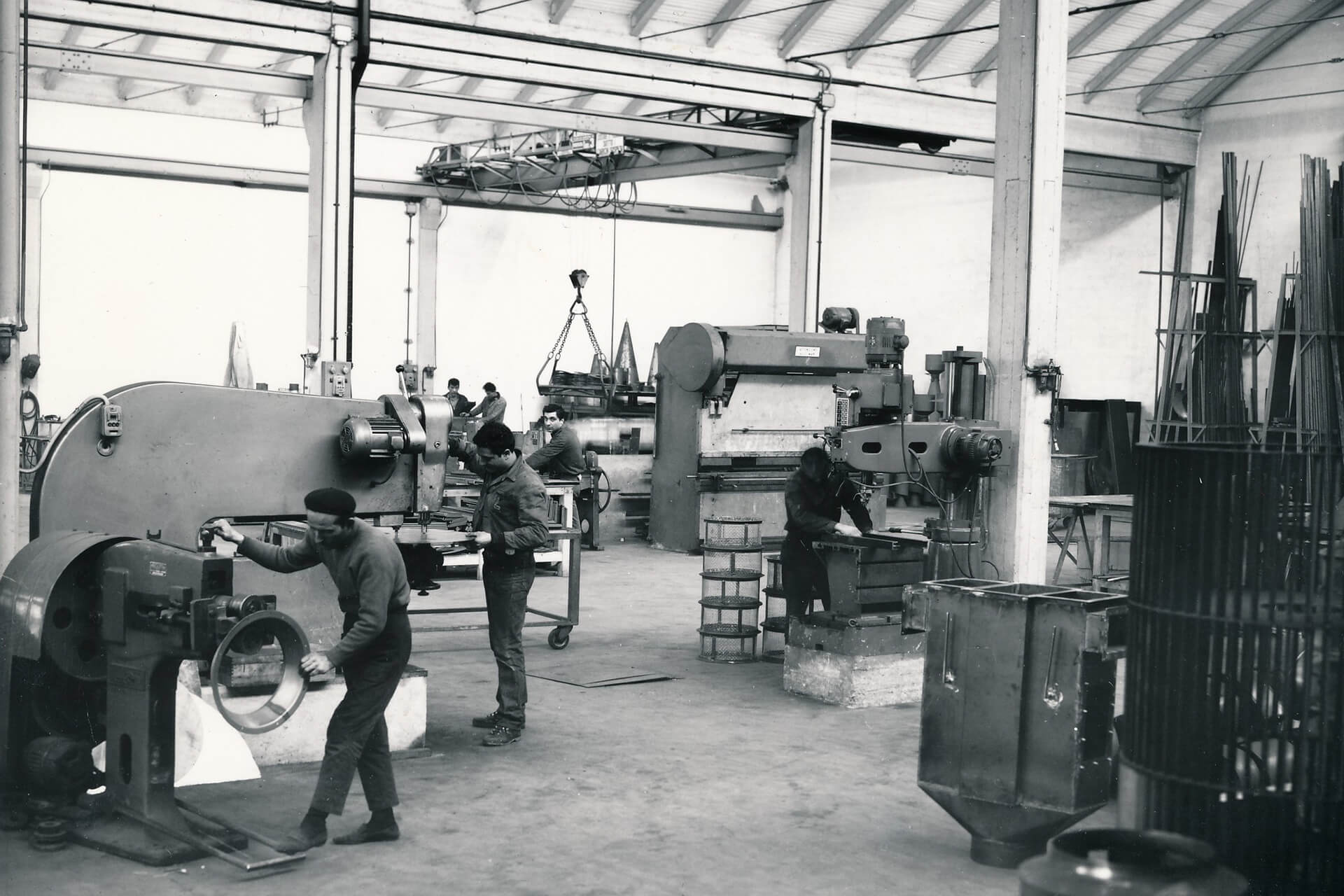

History

Workers in 1962

Founded in 1959 by Carlo Garanzini and Mario Saita, Saiver was born as a ventilation systems company. Evolving under the careful direction of the founders, the factory starts to produce air handling units (AHU) in the the 1960s.

Its products stand out on the market for their quality, quickly transforming the company into an established reality.

The construction of the first AHU in the 1960s

The company has always shown itself attentive to innovation, creating methods that have become standards in the sector. This trend has allowed Saiver products to achieve firsts of efficiency, resistance and quality, while always taking environmental protection into account.

Fans testing in 1985

To date, Saiver has 75 employees including highly experienced engineers, technicians and workers. The production site, located in Busnago (MB), has an area of 18000 square meters and guarantees a production capacity of 4000 AHU per year.

The company currently counts customers from various sectors in 44 countries around the world and important agreements with other leading companies.

Certifications

Saiver offers numerous quality guarantees. Each of its products is made of resistant materials and is subject to precise controls and continuous tests. The company's philosophy is also based on the drive for innovation through the constant improvement of production performance. The excellent performances that characterize all Saiver products allow to save energy, and to reduce CO2 emissions and waste of water.

Testing of an AHU

Saiver's units are the result of 60 years of continuous research and improvement, and have specific characteristics in relation to the sector for which they are intended. The design phase, in fact, takes into account the customer's requests, in order to efficiently respond to his needs.

Working phases on an AHU

Team

The staff is a very important part of Saiver's reality. In its expansion path, the company has trained employees with complete experience in the production of air treatment units. These in turn transmitted the same passion and expertise to the new workers.

Workers

Shared knowledge has been generated which has become a real corporate value over the years, confirmed by the stability of the staff and expressed in the everyday work. Furthermore, the high level of competence constitutes a solid basis from which to build continuous innovation-oriented development.

3D modeling of an AHU and CFD analysis